Built for Underground.

Not adapted to it.

The Inyathi is a true underground utility vehicle — designed from the ground up for mining environments.

Built to Last

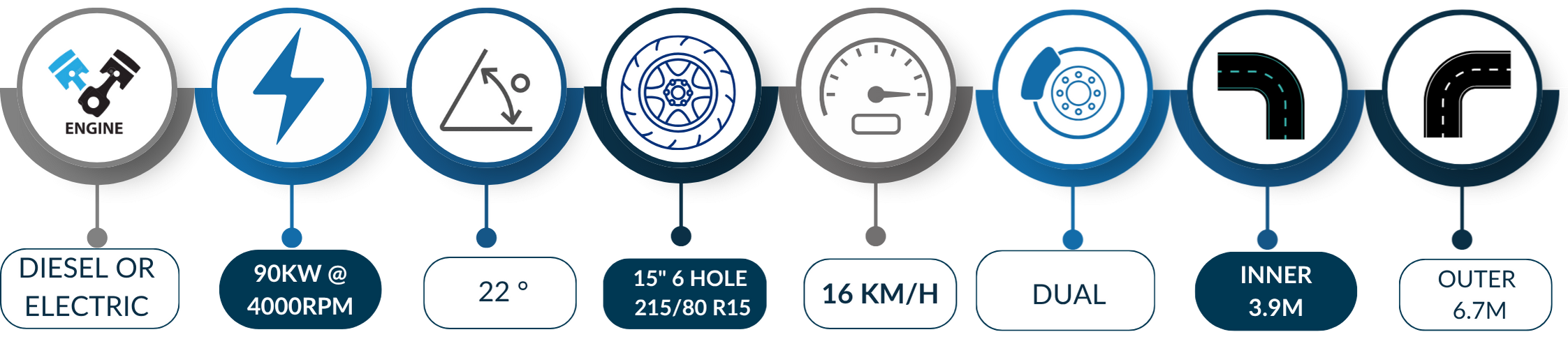

With its modular design, low profile configuration and dependable drivetrain the Inyathi is the underground LDV of choice for operations demanding safety, efficiency and long-term duarability

🔧 Built for Performance. Designed for Value

At its core is a robust round-tube chassis, with modular bolt-on components that simplify maintenance and reduce downtime.

This design allows for easy part replacement and upgrades

Making the Inyathi one of the most service-friendly underground LDV's available

Versatile meets local innovation

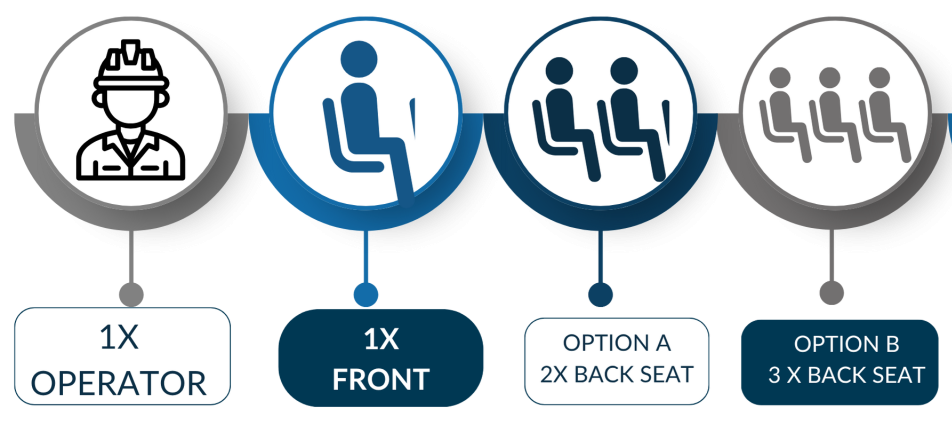

Available in both single and double cab configurations, the Inyathi DC2020 supports a wide array of loading bin options, including:

-

Standard flatbed

-

Boiler maker setup

-

Oil and diesel bowsers

-

Explosives carriers

With over 85% local content across the entire Inyathi range, JMS proudly supports South African manufacturing and supply chains.

🔒 Comfort amd Safety Underground

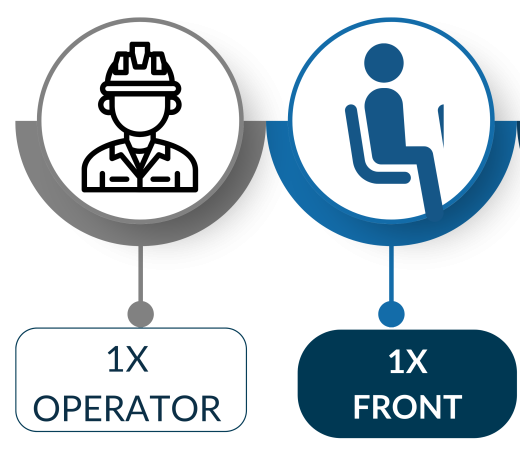

The ROPS/FOPS certified cabin is built with operator and passenger in mind.

Spacious interiors provide ample legroom and headroom,

ensuring comfort during long underground shifts.

🔧 Key Features

-

Modular Design: Round-tube chassis with bolt-on components for easy maintenance.

-

Proven Powertrain: 5L Diesel imported engine and drivetrain.

-

4x4 Low Profile: Designed for confined underground environments.

🛡 Safety First

-

ROPS/FOPS certified: Tested and approved by the University of Pretoria.

-

Ergonomic Interior: Prioritizes operator and passenger comfort.

-

Collision Avoidance Ready: CAS 9 solution with OEM-approved PDS interface.

🚚 Configurations & Load Options

Available in Single Cab and Double Cab with multiple bin options:

-

Flatbed

-

Boiler Maker Setup

-

Oil & Diesel Bowsers

-

Explosives Carrier

🚨Proudly local

-

Over 85% local content.

-

Designed and manufactured by Jarus Mining Supplies

🔗 Smart Integration

- Seamless compatibility with all Proximity Detection Systems (PDS)

- Holistic approach to underground

💡 Why Choose Inyathi?

-

Purpose-built—not modified from off-the-shelf vehicles

-

Proven performance from years of underground rebuild experience

-

A safe, robust, and cost-effective alternative to conventional LDVs

Jarus design and supply robust Underground Electric LDV's

Battery Electric Vehicles for Underground Mining Applications

Jarus Mining Supplies is proud to introduce its Battery Electric Light-Duty Vehicles (BE-LDVs)—engineered specifically for underground mining environments.

These electric models offer zero-emission operation, significantly reduce heat load, and eliminate noise pollution thanks to their silent electric motors—creating a healthier, safer workspace for underground personnel.

The first BE-LDV unit, currently operating at the Lebowa Shaft of the Mototolo Complex, has successfully validated the concept with over 95% availability and no major issues. With regenerative braking on downhill slopes, the vehicle can complete a full shift without recharging.

Just a few great points:

The E-LDV is designed to fulfil all safety requirements, improve staff health and safety, and ultimately lead to higher productivity.

-

ROPS and FOPS tested

-

Battery Operated

-

Eco Friendly

-

Parts easily available

-

Easy maintenance

-

Easy operation

-

3rd Party systems supported

-

Customer customization plans available

Health and Safety benefits include, but are not limited to, a decreased noise level and zero particle and carbon emissions.

Proven Performance & Intelligent Design

The Sesele and Inyathi BE-LDVs mirror the rugged design of their diesel counterparts, with a key difference under the hood.

Each unit is powered by a 41.5 kWh battery and a 60 kW / 100 kW electric motor, delivering up to 1000 Nm of continuous torque.

The vehicles offer a driving range of 180 km, with rapid charging capabilities:

-

120 minutes (0–100%, AC 3-phase)

-

43 minutes (0–100%, DC fast charge)

Safety-First Engineering

-

To address battery fire safety, a dielectric coolant system is integrated to prevent thermal runaway and enhance fire resistance.

Smart Mining Technology

Standard features include:

-

Fully electronic control system

-

CAN Bus integration

-

On-board diagnostics with data collection

-

Door brake lock system

Operational upgrades include:

-

Customer-specific data tracking

-

Collision Avoidance System (CAS) compliant with ISO-21815

-

Mine communication network connectivity

-

Automated brake testing

Enhanced Operator Control

For added safety and ease of use, BE-LDVs come equipped with:

-

Hill Descent Control

-

Cruise Control (ADSC)

-

Anti-Rollback and Anti-Rollforward systems